GaN Test Module Calibration

For detailed calibration instructions, refer to the specific User Guide for the custom GaN Test Module you are using. The following instructions provide an overview of the calibration procedure; your test module may be different.

The photographs in this section are representative and may not show your GaN Test module.

Set/Verify AC Line Frequency and Date/Time on the B2902A/B

The Keysight B2902A/B Source Measure Unit (SMU) is used only for the system calibration. Its factory default line frequency is set to 50 Hz. For specified accuracy, the line frequency must be changed to 60 Hz in those countries with a 60 Hz line frequency. To change the line frequency from the instrument front panel, press the following keys:

For setting to 50 Hz: More > System > PLC > 50 Hz

For setting to 60 Hz: More > System > PLC > 60 Hz

Optionally, set the Date and Time on the B2902A/B SMU, press the following:

System > Info > Date/Time

Calibration Setup

For detailed calibration instructions, refer to the specific User Guide for the custom GaN Test Module you are using. The following instructions provide an overview of the calibration procedure; your test module may be different.

Connecting Probes to the GaN Test Modules

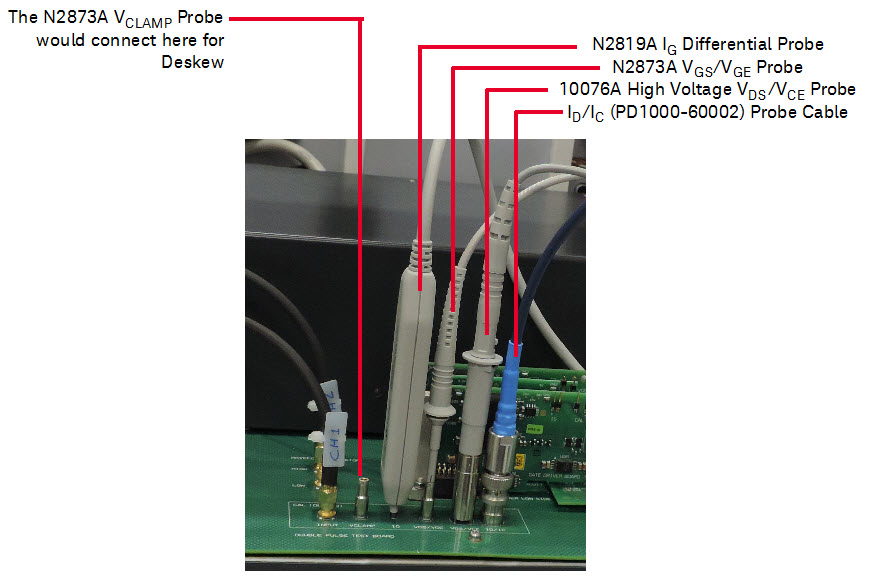

Oscilloscope probes connect to the Test Fixture Modules as follows:

- The DUT Module uses the following oscilloscope probes:

- BNC to SMA cable from the Coaxial Shunt Resistor (ID/IC) to the PD1000-60002 Oscilloscope Protection Probe.

- 10076A High Voltage, 100:1 Probe to the VDS/VCE probe socket.

- The Low Side Gate Driver Module has two oscilloscope probe connections:

- N2873A 10:1 Probe connects to the VGS/VCE probe socket

- N2819A Differential Probe connects to the IG probe socket terminals

- Optionally, if the Clamp Circuit Test Module is used:

- Do not install the N2819A Differential Probe on the IG probe socket terminals of the Low Side Gate Driver Module.

- N2873A 10:1 probe to the VCLAMP socket on the Clamp Module.

System Calibration Procedure

To begin the Calibration & Compensation process:

- Install the GaN Test Board on the PD1500A Test Fixture. Remove all DUT GaN devices from the Test Board.

Turn on the PD1500A Test System and allow it to warm-up for at least one hour.

- Remove the oscilloscope probes from the DPT test fixture and test modules. Do not remove them from the oscilloscope. Probe are re-installed as required for the calibration.

- Select Calibration & Compensation from the Settings drop-down menu.

- Follow all on-screen instructions.

Calibration Requirements

Calibration requires the B2902A/B Precision Source/Measure Unit (SMU) and the following cables/adapters:

- 1251-2277 Banana to BNC Adapter, quantity 1.

- 8121-2816 BNC to SMA Cable, 1 m, 50 Ohm, quantity 1.

- 1168B Standard Probe Kit, quantity 1.

IMPORTANT: Make certain the B2902A/B is set for the correct ac line frequency. See Set/ Verify AC Line Frequency and Date/Time on the B2902A/BAdditional Requirements:

- Perform the Oscilloscope Probe low frequency Compensation as the first step in the calibration.

- Unless instructed, both High-Side and Low-Side transistors should be removed from the DUT module (if possible).

- Perform the oscilloscope probe Deskew as the last calibration step.

All test instruments must be warmed up for at least 60 minutes at ambient temperature before starting the calibration procedure. Failure to allow warm up may result in inaccurate calibration.Initiate Calibration & Compensation Procedures

From the Double-Pulse Test Control tab in the PD1000A Control software, select: Settings > Calibration & Compensation.

Follow all on-screen instructions.

Low Frequency Oscilloscope Probe Offset Compensation

As the first step calibrating the Double-Pulse Test system, the oscilloscope probes must be adjusted for low frequency compensation. For this, the 10076C and N2873A passive probes have built-in compensation RC divider networks. The N2819A Active Differential Probe also requires offset compensation.

Allow the oscilloscope and probe to warm up at ambient temperature for a minimum of 60 minutes (1 hour) before performing the adjustment.Required Equipment

All equipment required for compensation and calibration were provided with the PD1500A test system. This includes:

- Spring hook and ground clips for passive oscilloscope probes.

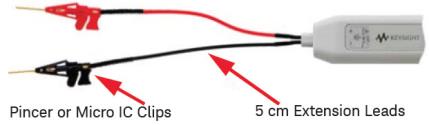

- 5 cm Extension Leads and either Pincer or micro IC clips for the N2819A Differential probe.

- Low Frequency Compensation trimmer/adjustment tools (small plastic screwdriver).

Compensating the 10076C and N2873A Probes

The Infiniium S-Series Oscilloscopes have a square wave reference signal available on the front panel to use for compensating the passive probes. Attach the spring hook and ground clip to the probe and then the square wave reference terminal.

- Refer to the N2873A Probe’s User Guide for instructions. A general description and procedure can also be found on page 5 (Hint #3) of the Keysight 8 Hints for Better Scope Probing.

- Connect the probe to the oscilloscope’s front-panel calibration output (a square wave label is seen near this output).

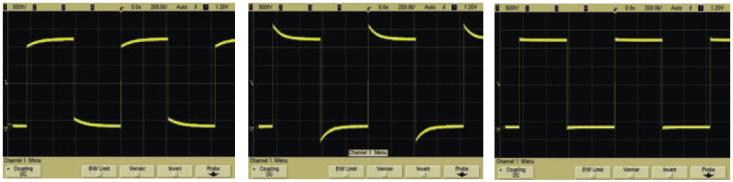

- Use the supplied trimmer tool to adjust the Low Frequency compensation to an optimum square wave response as shown below.

Adjust so that the square wave on the oscilloscope screen looks square.

Undercompensated Overcompensated Optimum Due to the 100:1 divider of the 10076C High Voltage Probe, the signal will appear to be very noisy. Therefore, it is beneficial to enable averaging in the Setup > Acquisition menu for suppressing this noise. Setting the number of averages to 16 will result in a clean signal.Compensating the N2819A Differential Probe

The N2819A Active Differential Probe also requires offset compensation. This is described below and in the N2818/9A Differential Probes User Guide. Use the trimmer tool supplied with the probe to perform the offset zero calibration.

- Connect the probe to an oscilloscope channel input. Turn on the oscilloscope and wait for a minimum of 20 minutes to allow the oscilloscope and probe to warm up.

- Using the probe's 5 cm Extension Leads and the Pincer or Micro IC Clip connection accessories, short the + and - inputs together.

- Press Control > Autoscale on the oscilloscope.

- Press the channel button for the probe and set the oscilloscope channel to DC Coupled mode.

- Set the oscilloscope to Averaging mode (Setup > Acquisition... > Averaging Enabled, x8 or higher) to reduce oscilloscope noise, if needed.

- Set the vertical scale of the oscilloscope to 100 mV/div.

- Using the offset adjustment tool that comes with the probe, adjust the probe offset voltage to zero volts.

In the Compensation & Calibration section of the Control Software, software, click the Skip button when you have completed the probe compensation.

System Calibration (Autocal) for GaN Devices

IMPORTANT – Calibration Information:

Several calibration-related procedures should be performed anytime the GaN Test Board is changed, anytime the ambient temperature changes ±5 °C, or anytime oscilloscope probes are changed.

Additionally, a complete Service Calibration is required annually for the DSOS104 oscilloscope, 33512B Waveform Generator, B2902A/B Precision Source/Measure Unit, the Heinzinger Power Supply test instruments and the Coaxial Shunt.

- The Gate Resistance Calibration and the Gate Current (IG) probe calibrations must NOT be performed with the GaN module installed. These steps can destroy the Gate Drive IC. This calibration must be done with the standard TO-247 DUT module,

- High Voltage Probe Calibration must be done with the standard TO-247 DUT module, not with the GaN Test Module.

- PD1000-60002 Protection Probe Calibration must be done with the standard TO-247 DUT module, not with the GaN Test Module.

Begin Calibration & Compensation

The following instructions are general calibration guidelines. Detailed information for your specific GaN Test Board is available from your Keysight Application Engineer.

- Do Not perform the IG Probe calibration. It can destroy the gate driver IC.

- High Voltage Probe and PD1000-60002 Protection Probe calibration must be one with the Si/SiC DUT modules and fixture, not with the GaN Test Board.

- Turn on the PD1500A Test System and allow all test instruments to warm-up for at least one hour.

- From the Settings drop-down menu select Calibration & Compensation.

- Perform the Oscilloscope Probe Compensation calibration step. Refer to the PD1000A Online Help file for detailed information about performing this step.

- If it is installed, remove the GaN module from the PD1500A Test Fixture.

- Install the standard TO-247 DUT module and Gate Drive modules.

- Perform the High Voltage Probe Calibration and the PD1000-60002 Protection Probe Calibration with the standard TO-247 DUT module and Gate Drive modules, not with the GaN Test Module.

- Remove the TO-247 DUT Module and Gate Drive Modules.

- Install the GaN Test Module to complete the calibration.

- Gate Voltage Calibration - VGS/VGE Probe

- Gate Voltage Source Calibration – VGS Output

- Clamp Circuit Probe Calibration – VCLAMP Probe

- Oscilloscope Probe De-Skew

- Follow all on-screen instructions for the calibration.

Gate Voltage Calibration - VGS Probe

Hardware Setup:

- Both High-Side and Low-Side DUTs must be removed from the GaN Test Module.

- Use the calibration cable and Banana - BNC adapter. Connect the SMA connector to the X1 connector on the GaN Test Module.

- Connect the banana plugs to Channel 1 Force terminals of the B2902.

- CON9 Open

- CON23 Shorted

- Ensure the VGS probe is connected.

Procedure:

After setting the hardware as describe above, click Start to perform the calibration and continue to the next step.

Gate Voltage Source - VGS Output

Hardware Setup:

- Both High-Side and Low-Side DUTs must be removed from the GaN Test Module.

- Use the calibration cable and Banana - BNC adapter. Connect the SMA connector to the X1 connector on the GaN Test Module.

- Connect the banana plug to Channel 1 Force terminals of the B2902.

- CON9 Shorted

- CON23 Shorted

- The N2873A VGS Gate Voltage Probe is optional and may be left connected from the previous Gate Voltage Calibration - VGS Probe calibration step.

Procedure:

After setting the hardware as describe above, click Start to perform the calibration and continue to the next step.

Gate Current Calibration - IG Probe

The Gate Current Calibration must NOT be performed with the GaN module installed. It will destroy the Gate Drive IC.

Procedure:

Skip this step.

Gate Resistance Calibration - RG

The Gate Resistance Calibration must NOT be performed with the GaN module installed. It will destroy the Gate Drive IC.

Procedure:

Skip this step.

High Voltage Probe Calibration - VDS Probe

This calibration step must be performed with a standard TO-247 DUT module and Gate Drive modules prior to the GaN modules calibration.

Clamp Circuit Probe Calibration - VCLAMP Probe

Hardware Setup:

- Both High-Side and Low-Side DUTs must be removed from the GaN Test Module.

- Using the U1168B Standard Probe Kit, connect the red cable from the B2902 SMU Channel 1 Force High Terminal to CON6 on the GaN Test Module. See the figure below.

- Using the U1168B Standard Probe Kit, connect the black cable from the B2902 SMU Force Low Terminal to CON8 on the GaN Test Module. .

- CON9 Shorted.

- CON23 Shorted.

Procedure:

After setting the hardware as describe above, click Start to perform the calibration and continue to the next step.

PD1000-60002 Protection Probe Calibration - ID/IC Probe

This calibration step must be performed with a standard TO-247 DUT module and Gate Drive modules prior to the GaN modules calibration.

Oscilloscope Probe Deskew

Connect Probes to Deskew Fixture

After the Oscilloscope Probe Compensation and System Calibration, the last step is to run Deskew. Deskew has the greatest impact on both On and Off Delay times and hence affects the total Switching Time. Both On and Off Switching Energies are also affected.

Hardware Setup:

Because the oscilloscope has only four input channels and the DPT test fixture uses only four oscilloscope probes at a time, then only four probes may be deskewed at one time. Typically, either the N2819A Differential Probe (for measuring IG) or the N2873A (VCLAMP) probe are used in a DPT test; rarely are they both used at the same time. Deskew the probes that you will be using in your test. Figure below shows the typical configuration for Deskewing the oscilloscope probes.

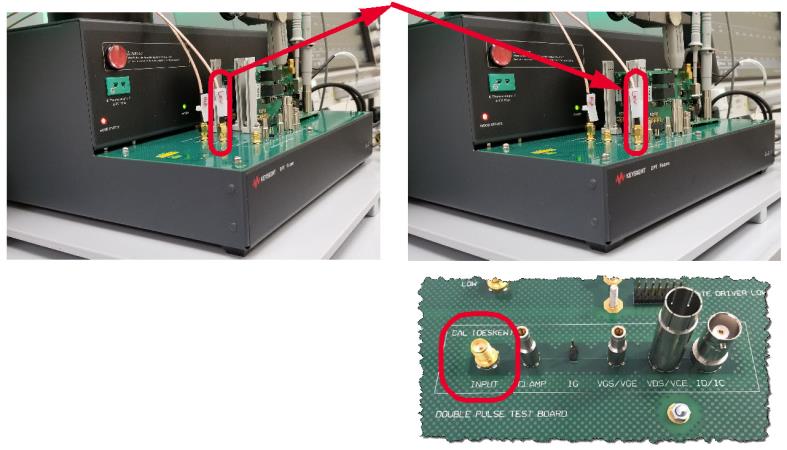

- Locate the Deskew oscilloscope probe connectors on the main Test Fixture. See figure below.

- Remove the SMA cable from the Low Side SMA connector on the Test Fixture and connect it to the Cal (Deskew) Input SMA connector.

The BNC connector (ID/IC) on the far right is for the PD1000-60002 Oscilloscope Protection probe cable that would normally connect to the Coaxial Shunt Resistor on the DUT Test Module.

- Connect the oscilloscope probes to the Deskew section of the Test Fixture.

Procedure:

- After setting up the oscilloscope probes in the Deskew fixture, click Start to perform Deskew calibration.

- When complete, return the oscilloscope probes to the appropriate connectors on the DUT and Test Modules.

- Return the SMA cable from the Cal (Deskew) Input SMA connector to the Low Side SMA connector on the Test Fixture.

This concludes the Compensation and Calibration procedure.

Top

Top